Loading capacity (m³/h): 2000m³/h

Machine power (Kw): 980KW

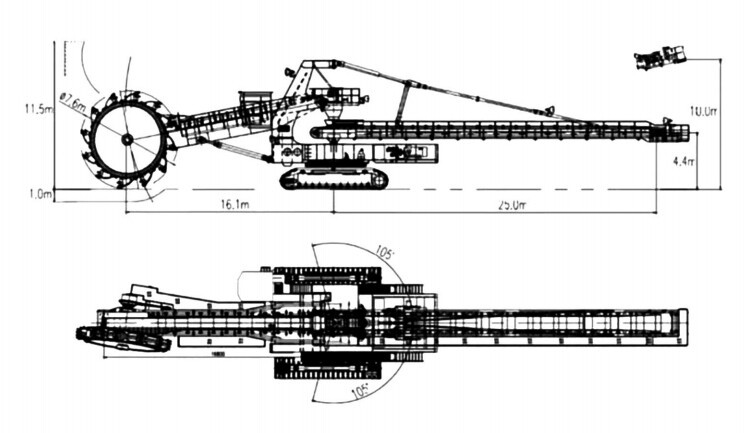

1. Physical Characteristics

The bucket wheel excavator can excavate materials from grade Ⅴ to grade X.

2. Machine Specifications

Rated loading capacity: 2000m³/h

Loading height: 10.0m

Power supply: Diesel generator set, city power; customer optional.

Supply voltage: 220/380V;

Supply frequency: 50HZ;

3. Machine Load

Total installed power: 980KW;

Total equipment weight: 360T;

4. Bucket Wheel Structure

Bucket wheel diameter: 7.6m;

Bucket wheel rotation speed: 2~8r/min;

Number of buckets: 12;

Bucket capacity: 0.445m³;

Drive device form: Motor-reducer;

Motor power: 550KW;

5. Bucket Wheel Luffing Structure

Luffing mechanism form: Hydraulic integrated amplitude variation;

Amplitude rising speed (bucket wheel center): 4m/min; customizable.

Amplitude lowering speed (bucket wheel center): 5m/min; customizable.

Luffing range: +12.8°~-13.2°; customizable.

Drive device: Motor-oil pump-double acting oil cylinder;

6. Main Applications

The bucket wheel excavator is particularly suitable for large-scale open-pit mining operations (e.g., highways, rivers, or dams) and storage yard applications. Due to significant differences in open-pit mining scale requirements, various different mining equipment can be adopted, and different machine types can form combined units as follows:

1. Giant bucket wheel excavator with conveyor bridge and transfer machine.

2. Bucket wheel excavator loading material onto heavy-duty trucks.

3. Bucket wheel excavator's discharge arm feeding material to conveyor at working face.

4. Combined unit consisting of bucket wheel reclaimer and transfer machine.

7. Product Highlights

(1) The bucket wheel excavator has high continuous production rate, large mining capacity, long service life, and can achieve good economic benefits.

(2) Standardized, serialized, and universalized, with optimized manufacturing process, more conducive to maintenance and repair.

(3) High degree of electrical automation, achieving automatic control and remote control.

(4) The bucket wheel excavator has strong cutting force, large excavation capacity, and high efficiency.

8. Main Technical Parameters:

JXLW-2000 Bucket Wheel Excavator

Please leave us a message